Project Dewatering Limited assisting civil works accross the UK

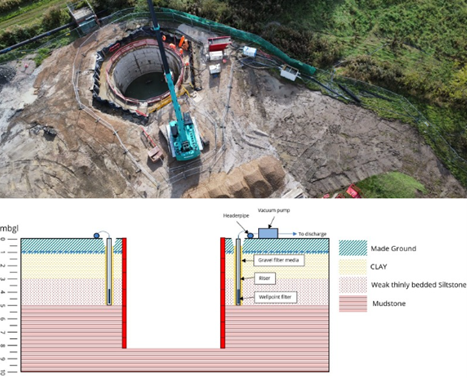

Chesterfield

Introduction

The large chamber excavation with a perimeter of 27m and a final depth of 8.3m required dewatering to ensure dry and safe working conditions during construction. The site investigation identified the soil sequence as silty and fine over competent mudstone, with shallow groundwater levels present.

The Works

Project Dewatering proposed a perimeter wellpoint system. Generally, wellpoints are not recommended for depths exceeding 6 to 7 metres. However, PDL considered the excavation method for the chamber and the depth of the mudstone layer and concluded that wellpoints would be effective. They were the preferred method for this type of geology compared to deep wells, as the wellpoints only needed to toe into the mudstone to dewater the more permeable upper strata. The wellpoints were installed by pre-augering and jetting, placed at 1.5m centres, and penetrated into the competent mudstone. Vacuum-assisted pumping from the wellpoints dewatered the upper strata while minimising any over-bleed from the top of the mudstone. The project has since concluded successfully, with the client installing the chamber to its final depth without groundwater ingress issues.

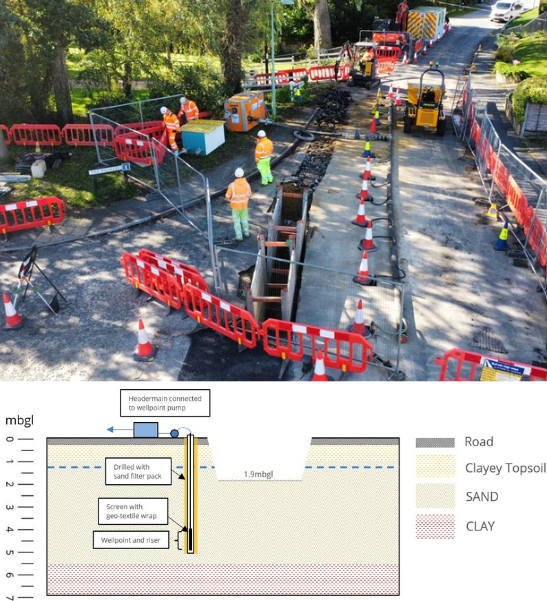

North Cove

Introduction

The work involved a new pipeline diversion and repairs on a street in North Cove. The proposed trench was 35m long and extended to a depth of 1.9m. Running sands were encountered during pre-start trial pits with the client noting a nearby recharge boundary. Groundwater levels were shallow and above the trench formation level.

The Works

Due to space constraints on site, the tarmac surface, and unknown ground conditions, PDL proposed to install the wellpoints using a window sampler rig and a concrete breaker. The wellpoints had to be placed with precision to avoid underlying services while remaining close enough to achieve sufficient drawdown. They were installed to a depth of 5m and spaced at 1.5m to 2m centers. The system performed excellently, allowing the new pipe installation and repair works to proceed without issue.

Newark-on-Trent

Introduction

PDL was contacted by the client to propose and install a dewatering system for the excavation of a pipeline and chamber. The total length of the proposed excavations was 165m, with a depth of up to 6.5m. PDL had prior experience working on the site and was familiar with the varying geology of silty SAND over CLAY over Mudstone/Siltstone.

The Works

PDL proposed single-sided wellpoints along the trench and around the perimeter of the chamber excavation. Given the fine and silty ground conditions, vacuum-assisted pumping from the wellpoint system was invaluable. PDL pre-augered and jetted the wellpoints to a depth of 7m and spaced them 1m apart. To minimise the pumping of fines, the wellpoints were backfilled with a gravel filter media and sharp sand. The system has since been decommissioned after successfully dewatering the excavations.

West Sussex Pumping Test

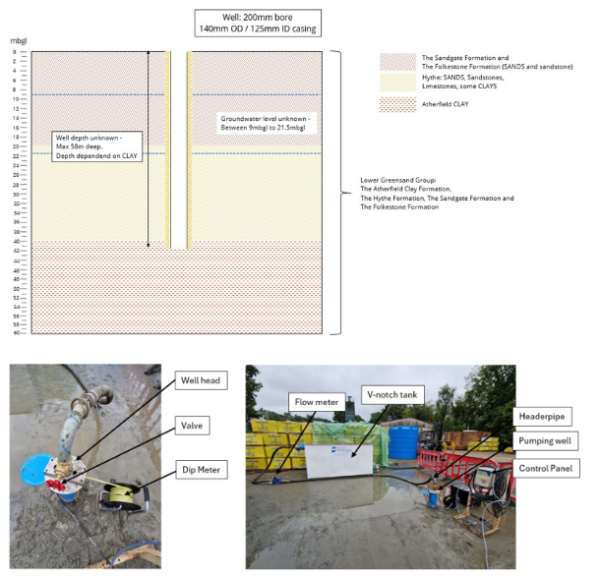

Introduction

A site in West Sussex needed to assess the yield of a newly installed well to determine if the aquifer could provide sufficient groundwater for commercial use. The well was installed to the full depth of the confined aquifer at 58m.

The Works

PDL provided all the necessary equipment, including pumps, control panels, generators, divers, discharge pipework, a calibrated flowmeter, a V-notch tank, a stopcock, and a flow valve, and conducted a 4-day pumping test. After verifying the equipment’s performance during an initial test, PDL carried out a step test to confirm the constant pumping rate for the long-duration test. Following the long duration test, the well was allowed to recover to its original level before the loggers were removed. PDL then processed and analyzed the pumping test data and produced a report for the client. Both the client and the EA representative were impressed by the quality of Project Dewatering’s work and setup, and we received positive feedback as a result.