Wellpoint and deepwell dewatering systems required to enable excavations in fractured MUDSTONE near Newark

Project Summary

The proposed works included a 100-meter perimeter excavation to a depth of 4.2 meters, followed by a 27-meter perimeter excavation for a pumping station to a depth of 10.7 meters. However, during the initial excavation, significant groundwater ingress occurred, halting the progress of the groundworkers. Analysis of the local geology revealed an expected strata sequence of clay over fractured mudstone. The observed inflow at the base, as noted by PDL, suggested that the fractured mudstone was under pressure. Removing soil from the top exacerbated this pressure, leading to rapid flooding of the excavation site.

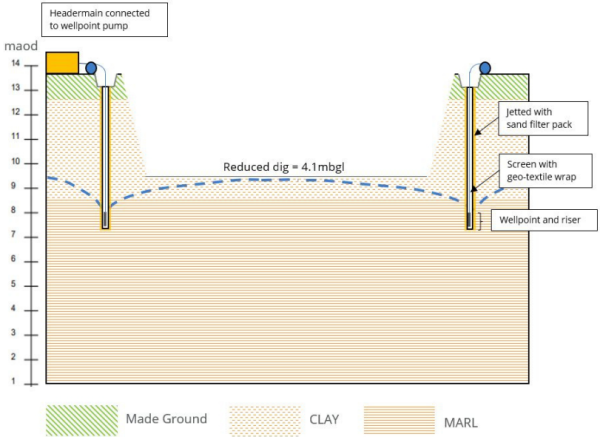

The Dewatering Strategy - 1st Phase

Project Dewatering Limited proposed the use of a wellpoint dewatering system around the external perimeter. The wellpoints were intended to alleviate some of the pressure in the mudstone while simultaneously pumping enough groundwater to provide PDL with a dry working platform at the reduced level.

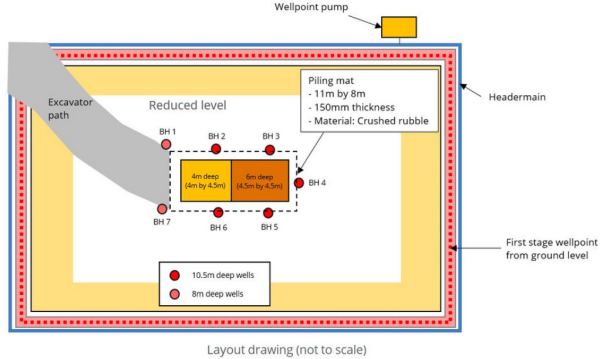

The Dewatering strategy - 2nd phase

With a dry working platform at the reduced level, PDL installed deep wells near the proposed deeper excavation. These deep wells would be closely spaced and extend into the fractured bedrock below the excavation formation level at a depth of 10.7 meters. The wells were equipped with 7.5 kW submersible pumps to ensure they could handle the high inflow rates.

Outcome

The simultaneous operation of wellpoints and deep wells ensured that the groundworkers could complete the proposed deeper excavation and finish concreting the base. Overall, the system performed admirably under very high-flow conditions. At its peak, PDL discharged over 35 liters per second from a relatively small and shallow excavation.